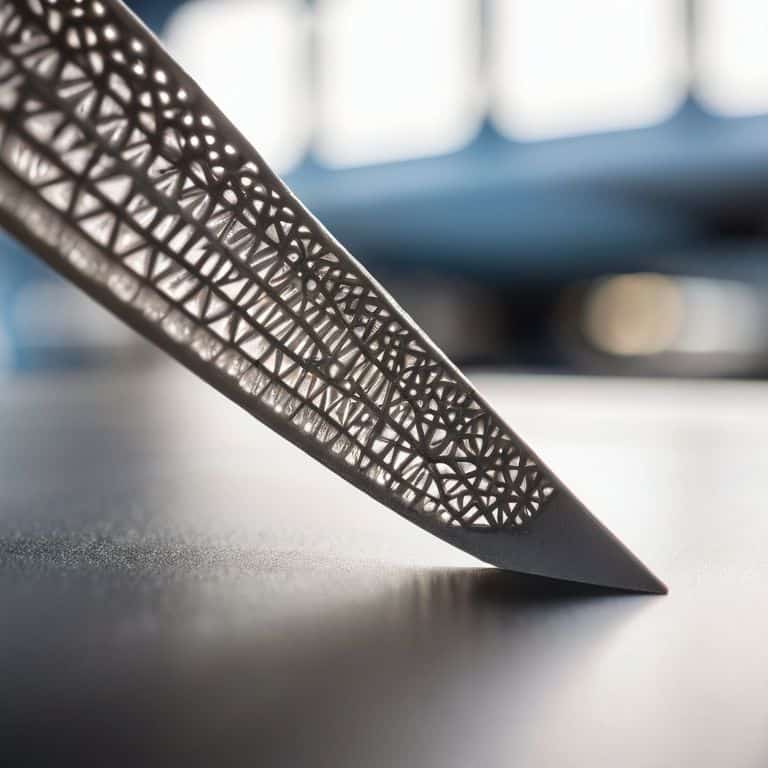

I still remember the first time I saw a 3D printed aircraft component up close – it was a game-changer. The way it combined complex geometry with unprecedented strength-to-weight ratio was a marvel. As someone who’s spent their career designing aircraft, I’ve always been fascinated by how 3D printing is used in aviation. But what really gets my blood pumping is the potential for this technology to revolutionize the industry. From reducing production times to enabling the creation of complex geometries that would be impossible with traditional manufacturing methods, 3D printing is poised to change the face of aviation forever.

As I delve into the world of 3D printing in aviation, I want to make one thing clear: this isn’t just about hype and buzzwords. It’s about the real, tangible benefits that this technology can bring to the table. In this article, I’ll be sharing my firsthand experience and knowledge to give you a no-nonsense look at how 3D printing is used in aviation. I’ll be covering the latest developments, the most promising applications, and the challenges that still need to be overcome. My goal is to provide you with a deep understanding of the science and technology behind 3D printing in aviation, and to inspire you to explore the endless possibilities that this technology has to offer.

Table of Contents

Revolutionizing Flight

As I delve into the world of additive manufacturing in aerospace, I’m constantly amazed by the impact it has on the aviation industry. The ability to create complex geometries and structures that cannot be produced with traditional manufacturing methods is a game-changer. For instance, 3D printed aircraft components can be designed to be lighter and stronger, which in turn can lead to significant fuel savings and reduced emissions.

The benefits of 3D printing in flight production are numerous, and one of the most significant advantages is the reduced lead time for production. With traditional manufacturing methods, producing a single component can take weeks or even months. However, with 3D printing, the same component can be produced in a matter of days. This not only saves time but also reduces costs. Furthermore, certification of 3D printed airplane parts is becoming more streamlined, which is a crucial step towards widespread adoption.

The future of 3D printing in aviation manufacturing looks promising, with many experts predicting that it will play a major role in shaping the industry. As the technology continues to evolve, we can expect to see even more complex and sophisticated components being produced. The aviation industry innovation trends are clearly pointing towards a future where 3D printing is an integral part of the manufacturing process.

Additive Manufacturing in Aerospace

As I delve into the world of additive manufacturing in aerospace, I’m reminded of the precision required to create complex aircraft components. This level of detail is crucial in ensuring the safety and efficiency of flight.

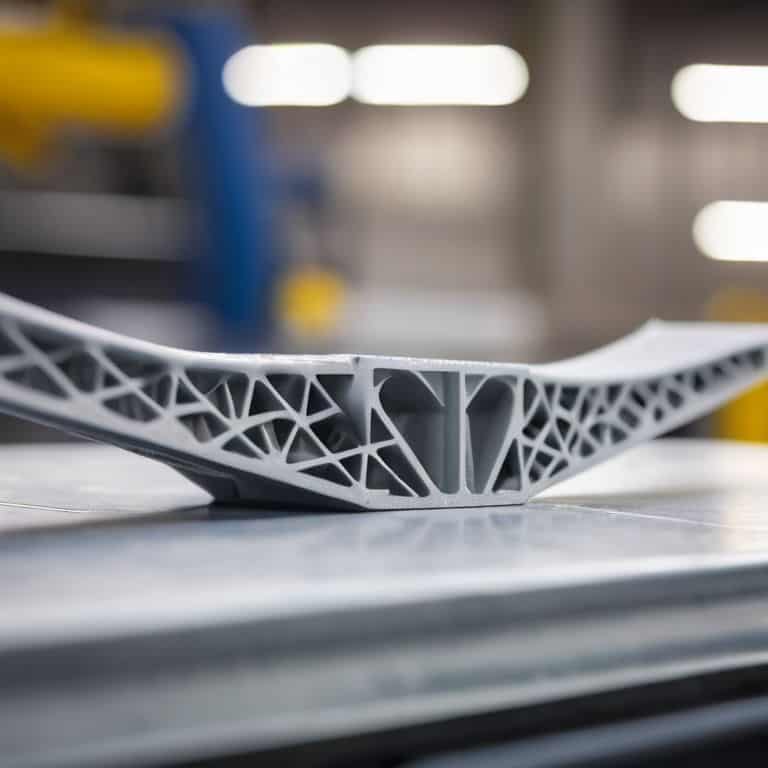

The use of additive layering in manufacturing has been a significant breakthrough, allowing for the creation of intricate geometries that cannot be produced through traditional methods.

Benefits of 3d Printing in Aviation

As I delve into the world of 3D printing in aviation, I’m excited to share the tangible benefits it brings to the table. One of the most significant advantages is the reduction in production time and cost. By leveraging additive manufacturing, companies can quickly produce complex parts and components, streamlining their supply chains and getting products to market faster.

The use of 3D printing in aviation also enables increased design flexibility, allowing engineers to create complex geometries and structures that would be impossible to produce with traditional manufacturing methods. This freedom to innovate has led to the development of lighter, stronger, and more efficient aircraft components, which in turn enhance overall flight performance and safety.

How 3d Printing Is Used

As I delve into the specifics of additive manufacturing in aerospace, it’s fascinating to see how 3D printing is being utilized to create complex aircraft components. One of the primary advantages of this technology is the ability to produce parts with intricate geometries that would be impossible to manufacture using traditional methods. This has led to significant advancements in the aviation industry innovation trends, with many companies now investing heavily in 3D printing research and development.

The benefits of 3D printing in aviation are numerous, ranging from reduced material waste to increased production efficiency. By using 3D printing, manufacturers can create parts with minimal excess material, resulting in significant cost savings. Additionally, the use of 3D printed aircraft components can lead to increased fuel efficiency, as the reduced weight of the parts can result in lower fuel consumption. This, in turn, can lead to reduced emissions and a more sustainable aviation industry.

The certification of 3D printed airplane parts is a critical step in the adoption of this technology. Regulatory bodies are working closely with manufacturers to establish standards and guidelines for the certification of 3D printed components. As the future of 3D printing in aviation manufacturing continues to evolve, it’s likely that we’ll see even more innovative applications of this technology, from the creation of complex engine components to the development of entirely new aircraft designs.

Certification of 3d Printed Airplane Parts

As I delve into the world of 3D printing in aviation, I’m often asked about the certification process for these innovative parts. It’s a crucial step, ensuring that each component meets the stringent safety standards of the industry. I’ve seen firsthand how meticulous this process can be, with regulatory bodies like the FAA scrutinizing every detail.

The certification of 3D printed airplane parts involves a rigorous testing regimen, pushing these components to their limits to guarantee they can withstand the stresses of flight. This meticulous approach is what makes 3D printing in aviation not just a novelty, but a reliable and efficient means of producing high-performance parts.

Future of 3d Printing in Aviation Manufacturing

As I look to the horizon, I see a future where additive manufacturing plays an even more pivotal role in aviation. The ability to create complex geometries and reduce material waste will continue to drive innovation.

The next generation of aircraft will likely feature more integrated systems and optimized structures, thanks to the versatility of 3D printing technology.

Taking Flight with 3D Printing: 5 Key Tips

- Leverage additive manufacturing for complex geometries that cannot be produced with traditional methods, enhancing aircraft performance and efficiency

- Implement rigorous testing and certification protocols for 3D printed parts to ensure they meet or exceed the standards of traditionally manufactured components

- Utilize 3D printing for rapid prototyping and design iteration, significantly reducing the time and cost associated with developing new aircraft components

- Explore the use of advanced materials and composites in 3D printing to create stronger, lighter aircraft structures that improve fuel efficiency and reduce emissions

- Collaborate with regulatory bodies and industry partners to establish standardized guidelines and best practices for the integration of 3D printed parts into commercial aircraft production

Key Takeaways: 3D Printing in Aviation

I’ve seen firsthand how 3D printing is revolutionizing the way we build aircraft, making flight safer and more efficient by enabling the rapid production of complex components

Additive manufacturing in aerospace is not just about cutting costs, but also about creating innovative designs that would be impossible to produce with traditional methods, such as customized aircraft parts with unique geometries

The future of 3D printing in aviation manufacturing holds tremendous promise, from certified airplane parts to entirely new aircraft designs, and it’s an exciting time to be an aerospace engineer, with the potential to make a real impact on the industry

The Future of Flight

3D printing is not just a tool in aviation; it’s a paradigm shift, enabling us to create complex, lightweight structures that were previously impossible to manufacture, and it’s this fusion of innovation and efficiency that will redefine the skies.

Simon Foster

Taking to the Skies: The Future of Aviation

As I reflect on the impact of 3D printing in aviation, it’s clear that this technology is revolutionizing the industry. From the benefits of additive manufacturing, such as increased efficiency and reduced material waste, to the certification of 3D printed airplane parts, the future of flight is being reshaped. The use of 3D printing in aviation has come a long way, and it’s exciting to think about what’s to come. Innovative designs and streamlined production processes are just the beginning, and I’m eager to see how this technology will continue to evolve.

As we look to the future, it’s inspiring to consider the potential of 3D printing to transform the skies. With its ability to create complex structures and reduce production time, this technology has the power to make air travel safer, more efficient, and more accessible. As an aerospace engineer and technical journalist, I’m thrilled to be a part of this journey, and I hope that my insights have inspired you to learn more about the * science of flight* and the incredible advancements being made in this field. The sky’s no longer the limit – it’s just the beginning.

Frequently Asked Questions

What are the most common types of aircraft components being produced with 3D printing?

I’ve worked with several components that are commonly 3D printed, including engine parts, satellite components, and even entire aircraft wings. But if I had to narrow it down, I’d say the most common ones are brackets, ducts, and other secondary structural elements – these are perfect candidates for additive manufacturing due to their complex geometries.

How does the use of 3D printing in aviation affect the overall weight and fuel efficiency of an aircraft?

By leveraging 3D printing, we can create complex geometries that reduce material usage, resulting in significant weight savings. This, in turn, enhances fuel efficiency. I’ve seen it in my own designs – optimized structures and reduced weight can lead to substantial fuel savings, making flight more economical and environmentally friendly.

What are the current limitations and challenges of using 3D printing for producing critical aircraft parts, such as engine components or structural elements?

Currently, limitations include material strength, scalability, and regulatory hurdles. For critical parts like engine components, we need to ensure 3D printed materials meet stringent safety standards, which can be a challenge. Additionally, scaling up production while maintaining precision is an ongoing hurdle.