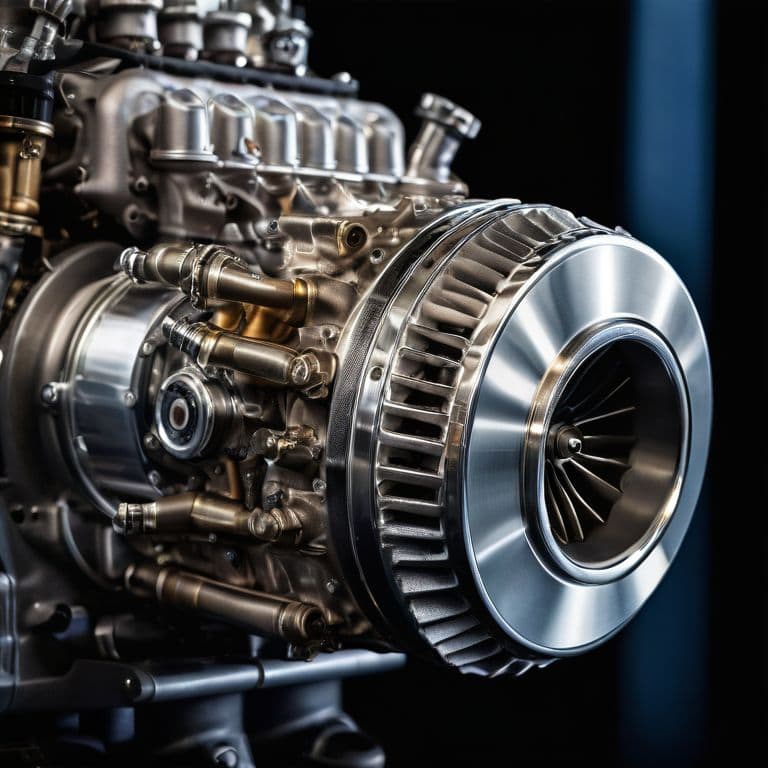

I still remember the first time I witnessed a jet engine in action – the sound was like nothing I’d ever heard before, a deafening roar that seemed to shake the very foundations of the airfield. As I delved deeper into the world of aerospace engineering, I began to appreciate the intricate dance of components that make these machines tick. But despite my fascination, I’ve always been frustrated by the overly complicated explanations of how jet engines work. It’s as if the complexity of the topic has become a barrier to understanding, rather than an invitation to explore. I’ve lost count of how many times I’ve seen people nod off when trying to grasp the basics of jet engine functionality, only to be left with a vague notion that it’s all about combustion and turbines.

As someone who’s spent their career designing aircraft, I’m here to tell you that the real magic lies not in the jargon, but in the elegant simplicity of the underlying principles. In this article, I promise to cut through the hype and provide you with a clear, no-nonsense explanation of how jet engines work. I’ll draw on my own experiences, from the design lab to the flight line, to illustrate the key concepts and mechanisms that make these incredible machines possible. By the end of this journey, you’ll have a deep understanding of the science behind jet engines, and a newfound appreciation for the ingenuity that goes into designing and building them.

Table of Contents

Unraveling Jet Engine Secrets

As I delve into the intricacies of jet engines, I’m reminded of the fundamental principles that govern their operation. The concept of gas turbine efficiency is particularly fascinating, as it plays a crucial role in determining the overall performance of the engine. By optimizing the design of the compressor and turbine blades, engineers can significantly improve the engine’s ability to generate thrust.

The history of jet engine development is a testament to human ingenuity and the relentless pursuit of innovation. From the early experiments with turbojet engines to the modern high-bypass turbofan designs, each iteration has brought significant improvements in efficiency, power, and reliability. As an aerospace engineer, I’m amazed by the complexity and sophistication of these systems, which have become the backbone of modern air travel.

In my experience, jet engine maintenance tips are often overlooked, yet they are essential for ensuring the longevity and safety of the engine. By understanding the underlying jet engine design principles, technicians can identify potential issues before they become major problems, thereby reducing downtime and improving overall efficiency. This attention to detail is what sets apart a well-designed engine from a truly exceptional one.

Gas Turbine Efficiency Uncovered

As I delve into the intricacies of gas turbine engines, I’m reminded of the importance of thermodynamic balance. It’s a delicate dance between pressure, temperature, and airflow, where even the slightest miscalculation can significantly impact efficiency. The gas turbine’s ability to harness energy from combustion is a marvel of modern engineering, and understanding its principles is crucial for appreciating the science behind flight.

The key to unlocking optimal performance lies in the _turbine’s compression ratio_, which determines how effectively the engine can extract energy from the exhaust gases. By carefully calibrating this ratio, engineers can coax remarkable efficiency from these powerful machines, making them the backbone of modern air travel.

Jet Engine Design Principles Explained

As I delve into the world of jet engine design, I’m reminded of the importance of efficiency in every component. From the compressor blades to the turbine nozzles, each part plays a crucial role in harnessing the energy released by combustion. The shape, size, and material of these components are carefully crafted to optimize performance, and it’s fascinating to see how these tiny details can make a significant difference in the overall power output.

The design process involves a deep understanding of fluid dynamics, which governs the behavior of gases as they flow through the engine. By applying principles such as Bernoulli’s equation and the concept of laminar flow, engineers can create a system that minimizes energy loss and maximizes thrust. This intricate dance of air, fuel, and metal is a testament to human ingenuity and the pursuit of innovation in aerospace engineering.

How Jet Engines Work Magic

As I delve into the intricacies of jet engine design principles, I am reminded of the sheer brilliance of these machines. The way they harness the power of combustion to generate thrust is a testament to human ingenuity. At the heart of every jet engine lies a gas turbine, which plays a crucial role in determining the engine’s overall efficiency. Gas turbine efficiency is a delicate balance of airflow, temperature, and pressure, and even the slightest miscalculation can have significant consequences.

When it comes to aircraft propulsion systems, jet engines are the epitome of performance and reliability. The history of jet engine development is a fascinating tale of innovation and perseverance, with pioneers like Frank Whittle and Hans von Ohain paving the way for modern designs. As I reflect on the evolution of jet engines, I am struck by the remarkable progress made in reducing jet engine noise reduction, making air travel safer and more comfortable for millions of people around the world.

In my experience as an aerospace engineer, I have come to appreciate the importance of meticulous jet engine maintenance tips in ensuring the optimal performance of these complex machines. By understanding the underlying principles of jet engine design and operation, we can unlock new possibilities for improvement and innovation, driving the next generation of aircraft propulsion systems forward.

History of Jet Engine Development Revealed

As I delve into the history of jet engine development, I’m reminded of the pioneering work of Sir Frank Whittle, who patented the first design for a jet engine in 1930. His innovative concept of using a turbine to drive a compressor, which would then generate a high-speed exhaust, laid the foundation for modern jet engines.

The development of jet engines accelerated rapidly during World War II, with significant advancements in materials and design. The first operational jet engine, the British Gloster E.28/39, made its maiden flight in 1941, marking a significant milestone in aviation history.

Jet Engine Noise Reduction Techniques

As I delve into the intricacies of jet engine design, I’m reminded of the importance of noise reduction. One of the most significant challenges in jet engine development is minimizing the noise generated by these powerful machines.

The key to quieter jet engines lies in optimizing fan design, which can significantly reduce the noise produced during operation.

Unlocking the Secrets of Jet Engines: 5 Essential Tips

- Understand the Core Principle: Jet engines operate on the principle of converting chemical energy into kinetic energy, which is then harnessed to produce thrust

- Master the Concept of Gas Turbine Efficiency: The efficiency of a jet engine is largely dependent on its ability to efficiently compress and expand gases, which directly affects its overall performance and fuel consumption

- Appreciate the Role of Airflow: The design of the engine’s intake and exhaust systems plays a critical role in determining the engine’s overall efficiency and power output, as smooth airflow is essential for optimal performance

- Recognize the Importance of Materials Science: The development of high-temperature resistant materials has been crucial in the advancement of jet engine technology, enabling engines to operate at increasingly higher temperatures and pressures

- Grasp the Significance of Maintenance: Regular maintenance is vital to ensure the optimal performance and longevity of a jet engine, as even minor issues can lead to significant decreases in efficiency and increases in fuel consumption over time

Key Takeaways: Unlocking the Power of Jet Engines

Jet engines work by harnessing the energy released by combustion, using a combination of air, fuel, and spark to generate a high-velocity exhaust gas that produces forward thrust

Efficient gas turbine design is crucial for optimal jet engine performance, with factors such as compressor ratio, turbine temperature, and nozzle design all playing critical roles in determining engine efficiency and power output

The evolution of jet engine technology has been marked by significant advances in materials science, aerodynamics, and noise reduction, resulting in modern engines that are not only more powerful and efficient but also quieter and more environmentally friendly

The Heart of Flight

The beauty of jet engines lies not just in their power, but in the elegant dance of thermodynamics and aerodynamics that unleashes it, a true marvel of human ingenuity where every component, every curve, and every combustion cycle is a testament to the relentless pursuit of efficiency and innovation.

Simon Foster

Conclusion: The Wonders of Jet Engines

As we’ve explored the intricacies of jet engines, from their design principles to their efficiency and historical development, it’s clear that these machines are a testament to human ingenuity and the power of aerodynamic innovation. We’ve seen how gas turbine efficiency is crucial for the performance of jet engines, and how advanced materials have played a significant role in their evolution. By understanding the science behind jet engines, we can appreciate the complexity and beauty of these systems that keep us safe in the sky.

As we conclude our journey into the world of jet engines, let’s not forget the magic of flight that they enable. The next time you board a plane, remember the brilliant engineering that goes into making that journey possible. It’s a reminder that the wonders of science and technology are all around us, waiting to be discovered and appreciated – and who knows, maybe one day you’ll be the one designing the next generation of jet engines, pushing the boundaries of what’s possible and inspiring a new generation of engineers and aviation enthusiasts alike.

Frequently Asked Questions

What is the role of compressor blades in a jet engine and how do they contribute to overall engine efficiency?

Compressor blades play a crucial role in a jet engine, responsible for compressing air to incredibly high pressures. Their curved design accelerates air rearward, converting kinetic energy into pressure energy, which is then mixed with fuel and ignited, producing thrust. Efficient blade design is key to minimizing energy loss and maximizing overall engine performance.

How do jet engines regulate temperature to prevent overheating during operation?

To regulate temperature, jet engines employ sophisticated cooling systems, including air and fuel circulation. As the engine operates, fuel is used to cool the turbine blades, while air from the compressor stage is diverted to cool the engine casing, preventing overheating and maintaining optimal performance.

What are the key differences between low-bypass and high-bypass jet engines in terms of performance and application?

Low-bypass engines excel in high-speed, high-thrust applications like fighter jets, while high-bypass engines prioritize efficiency, making them ideal for commercial airliners where fuel economy is key. The bypass ratio dictates this trade-off, with high-bypass engines producing more thrust from the fan, resulting in better fuel efficiency, but lower specific thrust.