I still remember the day I first grasped the significance of what is titanium’s role in aerospace. It was during a project where we were designing a new aircraft, and the question of using titanium came up. I was amazed by its unique properties – high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. As I delved deeper, I realized that titanium is not just a fancy material, but a game-changer in the aerospace industry. Its role is multifaceted, from reducing weight and increasing fuel efficiency to providing a safe and durable structure for aircraft.

As someone who’s spent 15 years in the trenches of aerospace engineering, I’m excited to share my knowledge with you. In this article, I promise to cut through the hype and provide a no-nonsense explanation of titanium’s role in aerospace. I’ll draw from my personal experience and provide real-world examples to illustrate the benefits and challenges of using titanium in aircraft design. My goal is to empower you with a deep understanding of this remarkable material and its applications, so you can appreciate the science behind flight and make informed decisions. Whether you’re an engineer, a student, or simply an aviation enthusiast, I invite you to join me on this journey to explore the fascinating world of titanium in aerospace.

Table of Contents

Unlocking Titaniums Aerospace Role

As I delve into the world of aerospace engineering, I’m reminded of the crucial role titanium plays in our industry. Its unique combination of _high strength-to-weight ratio_ and _corrosion resistance_ makes it an ideal material for various aircraft components. From engine components to fasteners, titanium’s properties have revolutionized the way we design and build planes.

In the context of _aerospace material selection_, titanium alloy properties stand out due to their exceptional performance at _high temperatures_. This is particularly important in aircraft engine component design, where materials are subjected to extreme conditions. The use of titanium in such applications has significantly improved engine efficiency and reliability. Moreover, titanium fastener technology has become a standard in the industry, providing a secure and durable means of assembling aircraft structures.

The _titanium corrosion resistance_ is another key aspect that has contributed to its widespread adoption in aerospace. By minimizing the risk of corrosion, titanium helps ensure the longevity and safety of aircraft components. As an engineer, I can attest that the careful selection of materials like titanium is essential for creating high-performance, reliable aircraft that can withstand the demands of flight.

Aerospace Material Selection Insights

As I delve into the world of aerospace materials, I’m reminded that titanium’s strength-to-weight ratio is a game-changer. This unique property allows engineers to design lighter, more fuel-efficient aircraft without compromising on safety. I’ve seen it in action, from the production of engine components to the creation of complex airframe structures.

When it comes to selecting materials for aerospace applications, material fatigue is a critical consideration. The repeated stress and strain on aircraft components can lead to catastrophic failures if not properly addressed. By understanding the properties of materials like titanium, engineers can design and build aircraft that withstand the rigors of flight, ensuring the safety of passengers and crew.

Decoding Titanium Alloy Properties

As I delve into the world of titanium alloys, I’m reminded of the crucial role they play in aerospace engineering. The unique combination of high strength, low density, and exceptional corrosion resistance makes titanium alloys an ideal choice for various aircraft components. From engine components to fasteners, titanium’s properties have revolutionized the way we design and build aircraft.

The _high strength-to-weight ratio_ of titanium alloys is particularly noteworthy, allowing for significant weight reduction without compromising on performance. This, in turn, enables aircraft to achieve better fuel efficiency, increased range, and improved overall performance. As an engineer, it’s fascinating to see how these properties come together to create a safer, more efficient flying experience.

What Is Titaniums Role in Aerospace

As I delve into the world of aerospace engineering, I’m constantly reminded of the crucial role of titanium in keeping our planes safe and flying high. One of the primary reasons titanium alloy properties make it an ideal choice for aerospace applications is its exceptional strength-to-weight ratio. This allows for the creation of lightweight yet robust components, which is essential for reducing fuel consumption and increasing overall efficiency.

When it comes to aerospace material selection, titanium is often the preferred choice due to its unique combination of properties. For instance, its high_temperature_titanium_applications make it perfect for use in engine components, where temperatures can reach extreme levels. Additionally, titanium’s natural corrosion resistance ensures that it can withstand the harsh conditions encountered during flight, reducing the need for maintenance and increasing the overall lifespan of the aircraft.

In my experience as an aerospace engineer, I’ve seen firsthand how titanium_fastener_technology has revolutionized the design of aircraft engine components. By utilizing titanium fasteners, engineers can create more efficient and durable designs, which in turn leads to improved performance and reduced maintenance costs. This is just one example of how titanium is pushing the boundaries of what’s possible in aerospace engineering, and I’m excited to explore more of its applications in the future.

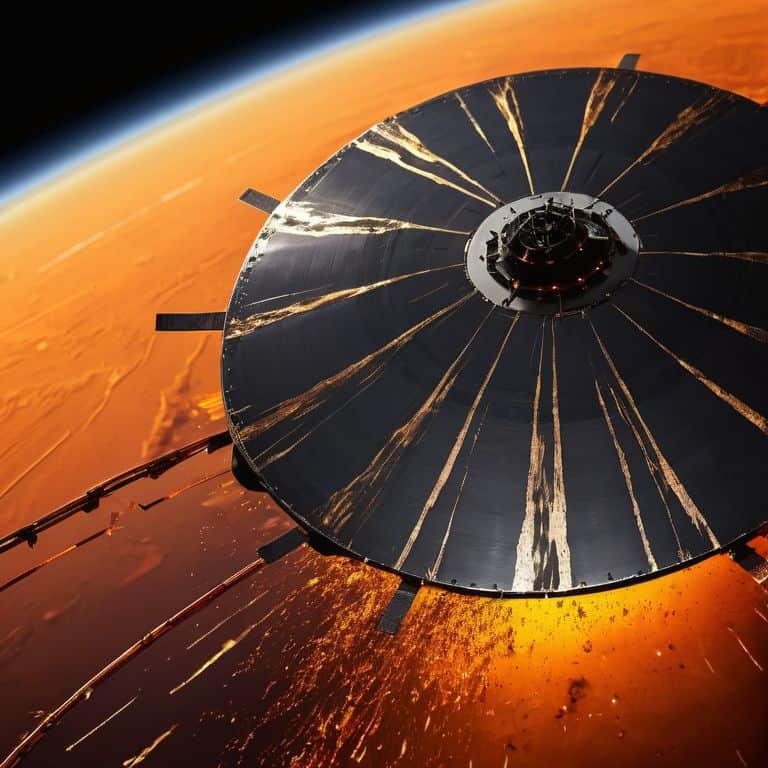

High Temperature Titanium Applications

As I delve into the world of high-temperature titanium applications, I’m reminded of the thermal resistance properties that make this metal a game-changer in aerospace engineering. Whether it’s engine components or heat exchangers, titanium’s ability to withstand extreme temperatures has proven invaluable.

In the context of aircraft design, high-temperature alloy development has been a significant focus area, enabling the creation of more efficient and durable engines. By leveraging titanium’s unique properties, engineers can optimize engine performance, leading to improved fuel efficiency and reduced maintenance costs.

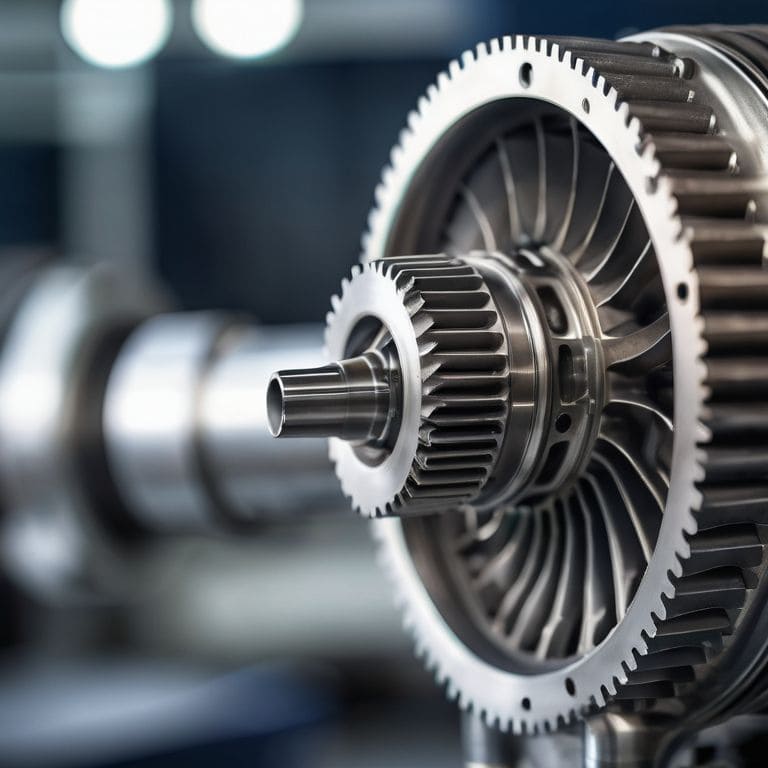

Titanium Fastener Technology Advances

As I delve into the world of titanium in aerospace, I’m reminded of the crucial role fasteners play in holding everything together. Titanium fastener technology has seen significant advances in recent years, allowing for stronger, lighter connections that can withstand the harsh conditions of flight.

The use of 3D printing in creating titanium fasteners has been a game-changer, enabling the production of complex shapes and structures that cannot be manufactured through traditional methods. This has led to improved efficiency and reduced weight, making aircraft safer and more fuel-efficient.

Uncovering the Wonders of Titanium in Aerospace: 5 Key Insights

- Titanium’s high strength-to-weight ratio makes it an ideal material for building lightweight yet robust aircraft components, such as engine components and fasteners

- Understanding the properties of titanium alloys is crucial for optimizing their use in aerospace applications, including their corrosion resistance and ability to withstand extreme temperatures

- The selection of titanium as a material in aerospace engineering is often driven by its unique combination of properties, including its high melting point, low density, and ability to withstand fatigue

- Advances in titanium fastener technology have played a significant role in improving the safety and efficiency of aircraft, enabling the use of stronger and more reliable joints and connections

- High-temperature titanium applications, such as in engine components, have revolutionized the aerospace industry by enabling the creation of more efficient and powerful engines, while also reducing maintenance needs and increasing overall aircraft performance

Key Takeaways: Titanium in Aerospace

I’ve discovered that titanium’s unique blend of high strength, low density, and exceptional corrosion resistance makes it an indispensable material in aircraft construction, particularly in high-temperature applications and critical fastener components

Through my experience as an aerospace engineer, I’ve learned that the careful selection of titanium alloys can significantly enhance an aircraft’s overall performance, safety, and efficiency, by minimizing weight while maintaining structural integrity

By embracing the latest advances in titanium fastener technology and high-temperature applications, the aerospace industry can continue to push the boundaries of flight, achieving greater fuel efficiency, reduced maintenance, and improved passenger safety, which is the ultimate goal of our profession

Unveiling the Titanium Advantage

To me, titanium represents the perfect synergy of form and function in aerospace engineering – its unique properties don’t just enhance performance, they redefine the boundaries of what’s possible in flight.

Simon Foster

Conclusion: The Titanium Advantage

As we’ve explored the role of titanium in aerospace, it’s clear that its unique combination of high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures makes it an ideal material for various aircraft components. From engine components to fasteners, titanium’s properties have revolutionized the way we design and build airplanes, making them safer, more efficient, and capable of withstanding the harsh conditions of flight. Whether it’s in the form of titanium alloys or 3D-printed parts, this metal has become an indispensable part of the aerospace industry.

As I reflect on the significance of titanium in aerospace, I’m reminded that the true magic of flight lies not in the mystery, but in the elegant simplicity of its underlying principles. The science of flight is a testament to human ingenuity and the pursuit of innovation, and as we continue to push the boundaries of what’s possible, materials like titanium will remain at the forefront of our endeavors, inspiring future generations of engineers and aviation enthusiasts to reach for the skies.

Frequently Asked Questions

How does titanium's high strength-to-weight ratio impact the overall performance and fuel efficiency of aircraft?

Titanium’s high strength-to-weight ratio is a game-changer for aircraft performance and fuel efficiency. By using titanium in critical components, we can reduce overall weight while maintaining strength, resulting in improved power-to-weight ratios and decreased fuel consumption – a win-win for both speed and sustainability.

What are the most significant challenges in manufacturing and integrating titanium components into aerospace structures?

As I’ve seen in my design days, manufacturing titanium components poses significant challenges, such as high machining costs and complex welding processes. Integrating these components into aerospace structures also requires careful consideration of stress concentrations and corrosion resistance to ensure seamless interaction with other materials.

In what ways is titanium being used in the development of new, high-performance aerospace applications, such as supersonic flight or advanced propulsion systems?

I’m excited to share that titanium is pivotal in next-gen aerospace, particularly in supersonic flight and advanced propulsion systems, due to its exceptional strength-to-weight ratio and heat resistance, enabling the creation of lighter, more efficient aircraft components that can withstand extreme temperatures and stresses.