I still remember the first time I saw a spacecraft’s heat shield in action – it’s mind-boggling to think about the temperatures it has to withstand, and it’s a challenge that keeps me up at night, wondering how we can make it even better. The challenges of heat shielding for spacecraft are often oversimplified, but the reality is that this is a complex, multifaceted problem that requires a deep understanding of fluid dynamics and materials science. As someone who’s spent their career designing aircraft, I’ve seen firsthand how a well-designed heat shield can be the difference between success and failure.

In this article, I promise to cut through the hype and provide a no-nonsense look at the challenges of heat shielding for spacecraft. I’ll draw on my experience as an aerospace engineer to provide practical insights and real-world examples, rather than just theoretical concepts. My goal is to give you a clear understanding of the key principles involved in heat shielding, and to show you how these principles can be applied in practice to overcome the challenges of space exploration. By the end of this article, you’ll have a deeper appreciation for the science behind heat shielding, and a better understanding of how it’s used to keep spacecraft safe.

Table of Contents

Beneath the Blaze

As I delve into the world of heat shielding, I’m reminded of the advanced ceramic materials that have revolutionized the field. These materials have enabled the creation of more efficient heat shields, capable of withstanding the extreme temperatures generated during atmospheric reentry. The _spacecraft thermal protection systems design_ is a complex process, requiring careful consideration of various factors, including the type of material used, its thickness, and its shape.

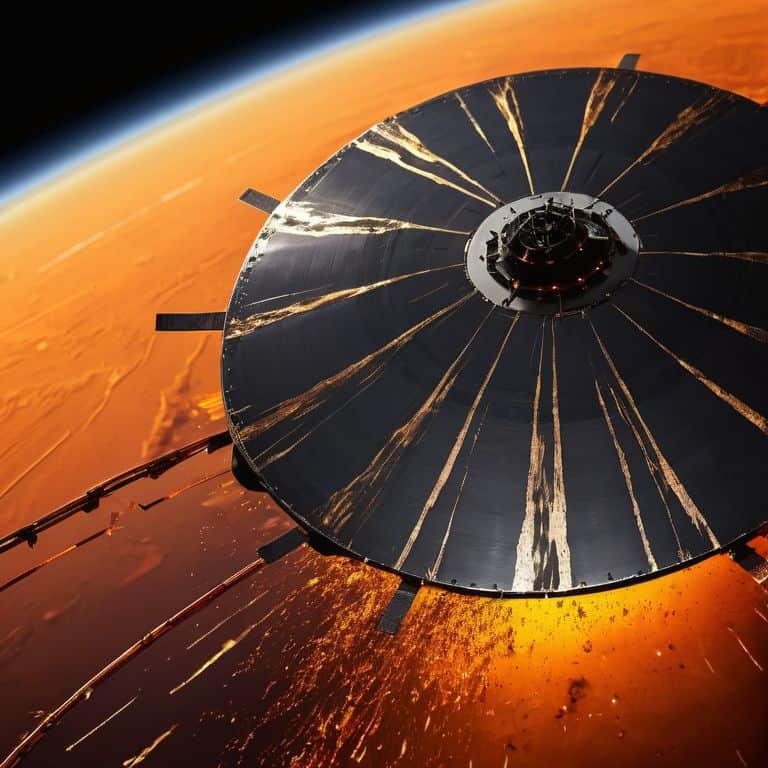

One of the most fascinating aspects of heat shielding is the _heat shield ablation mechanisms_. Ablation refers to the process of material being slowly eroded away due to the intense heat, and it’s a crucial aspect of heat shield design. By understanding how different materials ablate, engineers can create more effective heat shields that can withstand the harsh conditions of space. I’ve spent countless hours studying the reusable heat shield technologies, and I’m amazed by the progress that’s been made in this area.

The key to successful heat shielding lies in understanding the principles of _aerodynamic heating_ during atmospheric reentry. As a spacecraft enters the Earth’s atmosphere, it generates a tremendous amount of heat due to friction, and the heat shield must be able to withstand this heat without failing. By using composite materials for spacecraft insulation, engineers can create heat shields that are not only effective but also lightweight and durable.

Advanced Ceramic Heat Shields

As I delve into the world of advanced heat shielding, I’m reminded of the crucial role ceramic materials play in protecting spacecraft from extreme temperatures. The properties of these materials allow them to withstand intense heat fluxes, making them an ideal choice for heat shield construction.

In my experience, optimizing thermal protection is key to ensuring the structural integrity of a spacecraft. This involves carefully selecting and designing ceramic heat shields to meet specific mission requirements, taking into account factors such as re-entry speeds and atmospheric conditions.

Aerodynamic Heating Secrets

As I delve into the world of heat shielding, I’m reminded of the aerodynamic heating that occurs during re-entry. This phenomenon is a critical consideration for spacecraft designers, as it can cause temperatures to soar, potentially damaging the vehicle’s structure.

The key to mitigating this effect lies in understanding the boundary layer, a region of the atmosphere where the air is compressed and heated due to friction with the spacecraft’s surface. By carefully designing the spacecraft’s shape and materials, engineers can reduce the impact of aerodynamic heating, ensuring a safer and more controlled re-entry.

Challenges of Heat Shielding

As I delve into the intricacies of heat shielding, I’m reminded of the complex interplay between materials science and aerodynamics. The design of spacecraft thermal protection systems is a delicate balancing act, where even the slightest miscalculation can have catastrophic consequences. I recall a particularly challenging project where we had to develop advanced ceramic materials for heat shields that could withstand the intense heat generated during atmospheric reentry.

One of the most significant hurdles in heat shield design is heat shield ablation mechanisms, which can lead to a loss of material and reduced effectiveness over time. To mitigate this, researchers have been exploring reusable heat shield technologies that can withstand multiple reentries without significant degradation. This is an area of ongoing research, with significant potential for innovation and improvement.

In my experience, the key to successful heat shield design lies in understanding the aerodynamic heating during atmospheric reentry. By carefully modeling and simulating these complex phenomena, engineers can develop more efficient and effective thermal protection systems. The use of composite materials for spacecraft insulation has also shown great promise in reducing heat transfer and improving overall system performance.

Composite Insulation Breakthroughs

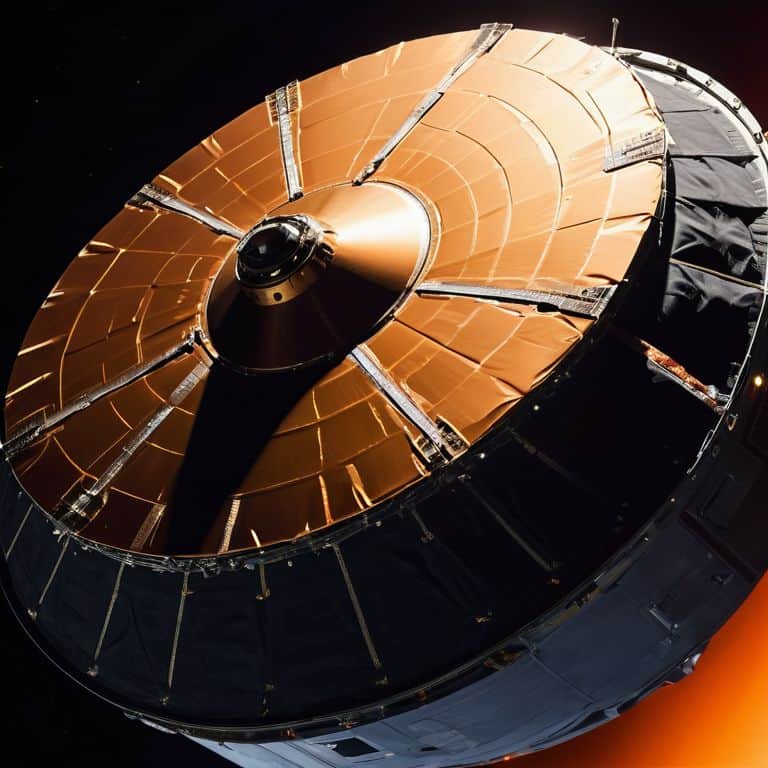

As I delve into the world of composite insulation, I’m reminded of the complex interplay between materials and temperatures. The quest for efficient heat shielding has led to some remarkable advancements in this field. By carefully crafting composite materials, engineers can now create insulation that is not only lightweight but also incredibly effective at withstanding extreme temperatures.

The use of multilayered composites has been a significant breakthrough in this area, allowing for tailored thermal properties that can be adjusted to meet specific mission requirements. This has opened up new possibilities for spacecraft design, enabling the creation of more efficient and reliable heat shields that can protect both the crew and electronic systems from the intense heat generated during re-entry.

Reusable Technologies Uncovered

As I delve into the world of reusable technologies, I’m reminded of the significance of thermal protection systems in modern spacecraft design. These systems are crucial for withstanding the extreme temperatures generated during re-entry into the Earth’s atmosphere. By developing reusable heat shields, engineers can significantly reduce the cost of access to space, making it more feasible for frequent launches and sustained space exploration.

The use of advanced materials in reusable technologies has been a game-changer for the industry. By incorporating these materials into heat shield designs, spacecraft can now survive the intense heat of re-entry without suffering significant damage, thereby enabling reuse and reducing the need for costly replacements.

Navigating the Inferno: 5 Crucial Considerations for Spacecraft Heat Shielding

- Understand the Dynamics of Aerodynamic Heating: It’s essential to grasp how friction-generated heat during re-entry affects the spacecraft’s surface, as this knowledge informs the design of effective heat shields

- Select Materials Wisely: The choice between traditional ablative materials and advanced ceramic or composite materials can significantly impact the heat shield’s performance and the spacecraft’s overall durability

- Balance Protection with Weight: Heat shields must provide adequate protection without compromising the spacecraft’s payload capacity or maneuverability, making material selection and design optimization critical

- Leverage Computational Fluid Dynamics (CFD): CFD simulations can predict heat loads and flow patterns around the spacecraft, enabling more accurate design and testing of heat shield systems under various re-entry scenarios

- Prioritize Reusability and Maintenance: As the space industry moves towards reusable vehicles, heat shields must be designed not only for peak performance but also for survivability and ease of refurbishment to reduce mission costs and enhance sustainability

Key Takeaways from the Challenges of Heat Shielding for Spacecraft

I’ve come to realize that the most critical aspect of heat shielding is not just the material used, but how it interacts with the surrounding environment, particularly during re-entry, where temperatures can soar to extreme levels

The development of advanced ceramic heat shields has been a game-changer, offering unparalleled protection against the intense heat generated by friction during atmospheric re-entry, and I’m excited to see where this technology will take us in the future

Through the lens of reusable technologies and composite insulation breakthroughs, it’s clear that the future of space exploration will be shaped by our ability to innovate and push the boundaries of what’s possible in heat shielding, and as an engineer, I couldn’t be more thrilled to be a part of this journey

Unveiling the Inferno

The art of heat shielding for spacecraft is not just about withstanding the furnace of re-entry, but about orchestrating a delicate ballet of materials and design to protect the fragile dance of human innovation within.

Simon Foster

Conclusion: Navigating the Flames of Innovation

As I reflect on the challenges of heat shielding for spacecraft, it’s clear that our journey has been one of continuous innovation. From the aerodynamic heating secrets that govern the behavior of heat shields during reentry, to the development of advanced ceramic heat shields that can withstand temperatures exceeding 2,000 degrees Fahrenheit, each breakthrough has paved the way for more ambitious space exploration. The reusable technologies and composite insulation breakthroughs we’ve discussed not only underscore the complexity of this challenge but also highlight the ingenuity of engineers and researchers in this field.

As we push the boundaries of space travel, it’s essential to remember that the pursuit of efficient heat shielding is not just about overcoming a technical hurdle, but about expanding humanity’s presence in space. By continuing to invest in research and development, and by fostering a community that values collaboration and knowledge-sharing, we can create a future where space travel is safer, more efficient, and accessible to all. The flame of innovation that drives us to solve the challenges of heat shielding will, in the end, illuminate the path to a brighter, more extraordinary future.

Frequently Asked Questions

What are the most significant materials science challenges in developing heat shields that can withstand the extreme temperatures generated during spacecraft re-entry?

For me, the biggest materials science hurdle is creating heat shields that can endure the intense friction and heat of re-entry, which can reach up to 3,000 degrees Fahrenheit. I’m fascinated by the potential of advanced ceramic and composite materials to solve this problem, as they offer exceptional thermal resistance and lightweight properties.

How do engineers balance the trade-offs between heat shield weight, thickness, and thermal protection to optimize spacecraft performance and safety?

To balance heat shield trade-offs, I consider the ‘thermal protection vs. weight’ dilemma. Thicker shields provide better protection but add weight, affecting spacecraft performance. I optimize by selecting materials with high thermal resistance-to-weight ratios, like advanced ceramics, and using clever design techniques, such as ablative shielding, to minimize weight while maintaining safety.

What role do advanced computational models and simulation tools play in designing and testing heat shield systems for next-generation spacecraft?

I rely heavily on advanced computational models and simulation tools to design and test heat shield systems. These tools allow me to simulate extreme temperatures and conditions, optimizing shield performance and reducing the need for physical prototypes, which saves time and resources.