I still remember the first time I saw carbon fiber being used in an airplane’s design. It was during my early days as a design engineer, and I was amazed by its potential to revolutionize the way we build aircraft. The use of carbon fiber in airplanes has been a game-changer, offering a unique combination of strength, lightweight, and corrosion resistance. As someone who’s spent 15 years in the industry, I’ve seen firsthand how it’s transformed the way we approach aircraft design.

In this article, I promise to cut through the hype and provide you with a no-nonsense look at the use of carbon fiber in airplanes. I’ll share my personal experiences, technical insights, and lessons learned from working with this incredible material. My goal is to give you a clear understanding of how carbon fiber is used in aircraft design, its benefits, and its limitations. By the end of this article, you’ll have a deeper appreciation for the science behind carbon fiber and its role in shaping the future of aviation. Whether you’re an aviation enthusiast or an industry professional, I’m excited to share my knowledge with you and explore the fascinating world of carbon fiber in airplanes.

Table of Contents

Carbon Fiber Revolution

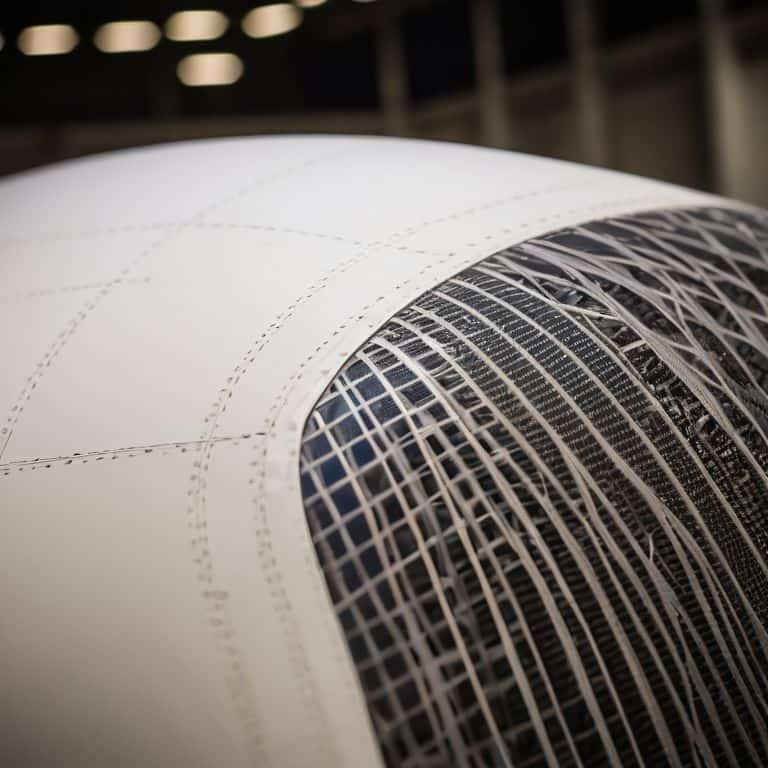

As I delve into the carbon fiber revolution, I’m reminded of my early days as a design engineer, where we would spend countless hours brainstorming ways to reduce aircraft weight without compromising strength. One of the most significant breakthroughs came with the introduction of carbon fiber reinforced polymers in aviation, which allowed us to create stronger, lighter structures that could withstand the rigors of flight. This innovation has been a game-changer, enabling us to push the boundaries of what’s possible in aircraft design.

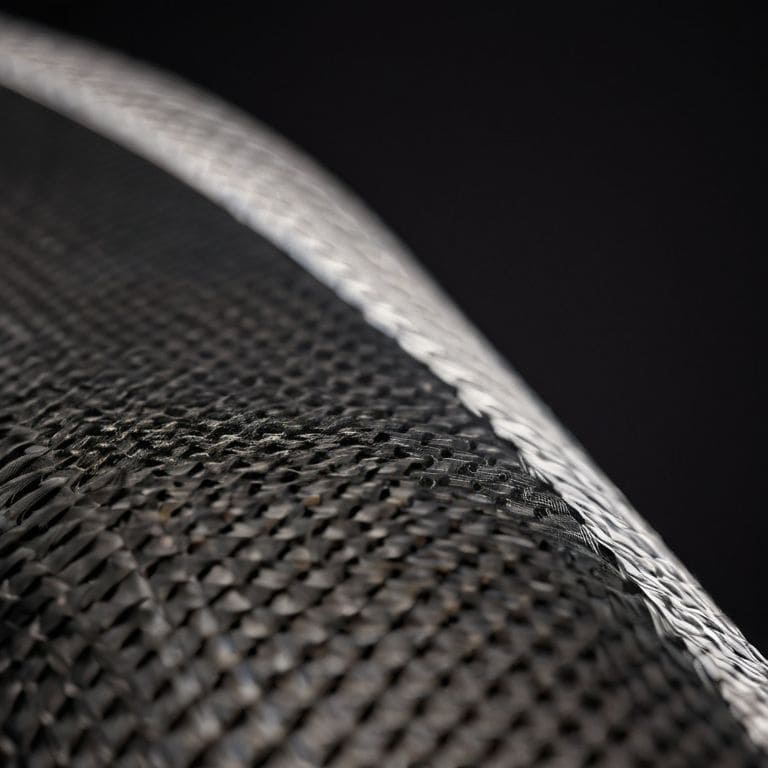

The benefits of advanced composite materials for airplanes are multifaceted. Not only do they offer significant weight reduction, but they also provide improved durability and resistance to fatigue. In comparison to traditional materials like aluminum, carbon fiber vs aluminum in aircraft construction is a clear win for the former, offering a substantial increase in strength-to-weight ratio. This has significant implications for fuel efficiency, as lighter aircraft require less energy to propel, resulting in reduced emissions and operating costs.

As we look to the future of carbon fiber in aerospace, it’s exciting to consider the potential applications of this technology. With ongoing research into sustainable aviation materials, we may soon see the development of even more efficient and environmentally friendly aircraft. The use of carbon fiber is just the beginning, and I’m eager to see how this technology continues to evolve and shape the industry. By embracing innovative materials and design techniques, we can create a new generation of aircraft that are not only more efficient but also more sustainable, paving the way for a cleaner, greener future in aviation.

Fibre Futures Advanced Composites

As I delve into the world of advanced composites, I’m excited to explore the fibre innovations that are redefining the boundaries of flight. The use of advanced materials is allowing us to push the limits of what’s possible in aircraft design, enabling the creation of stronger, lighter, and more efficient structures.

The future of flight is being shaped by cutting-edge materials that offer unparalleled performance and durability. By leveraging these advanced composites, we can create aircraft that are not only more fuel-efficient but also more sustainable, paving the way for a new generation of flying machines that are capable of achieving unprecedented heights.

Lighter Skies Carbon Fiber Weight Reduction

As I delve into the benefits of carbon fiber in airplane manufacturing, one aspect that stands out is its potential for significant weight reduction. By utilizing carbon fiber, engineers can create structures that are not only stronger but also lighter, which in turn leads to improved fuel efficiency and reduced operating costs.

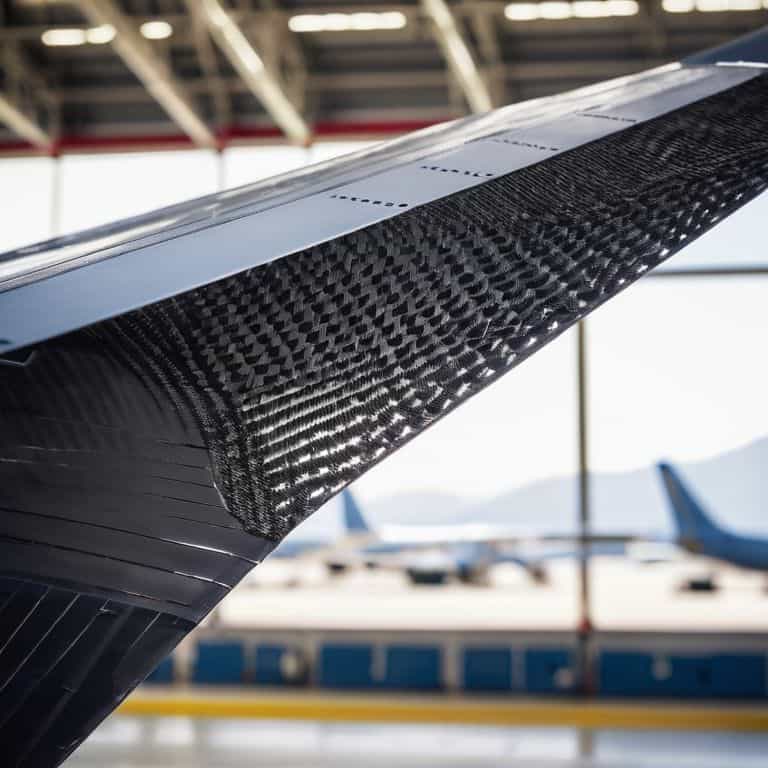

The use of carbon fiber enables the creation of optimized aerodynamic designs, allowing for a more streamlined flight experience. This is particularly important in the development of high-performance aircraft, where every ounce of weight savings can result in improved speed and maneuverability.

The Use of Carbon Fiber in Airplanes

As I delve into the world of carbon fiber reinforced polymers in aviation, I’m reminded of the significant impact it’s had on aircraft design. The integration of carbon fiber has enabled manufacturers to create stronger, lighter structures that enhance overall performance. This is particularly evident in the production of advanced composite materials, which have become a staple in modern airplane construction.

One of the primary advantages of using carbon fiber is its ability to reduce weight while maintaining strength, a concept that’s crucial for aircraft weight reduction techniques. By leveraging this property, engineers can design more efficient aircraft that consume less fuel and produce fewer emissions. The comparison between carbon fiber vs aluminum in aircraft construction is a notable one, as the former offers a significant reduction in weight without compromising on durability.

The future of carbon fiber in aerospace looks promising, with ongoing research focused on developing sustainable aviation materials. As the industry continues to evolve, it’s likely that we’ll see even more innovative applications of carbon fiber in airplane design. With its unique properties and numerous benefits, it’s clear that carbon fiber will play a vital role in shaping the future of carbon fiber in aerospace.

Carbon vs Aluminum the Aerospace Debate

As I delve into the specifics of carbon fiber in aircraft construction, I often find myself at the center of a longstanding debate: carbon vs aluminum. The aerodynamic benefits of carbon fiber are undeniable, allowing for sleeker, more streamlined designs that slice through the air with ease. This has significant implications for fuel efficiency and overall performance.

In my experience, the choice between carbon fiber and aluminum ultimately comes down to structural integrity. While aluminum has traditionally been the material of choice for its strength and durability, advances in carbon fiber technology have made it a viable alternative. I’ve seen firsthand how carbon fiber can be crafted to provide exceptional strength-to-weight ratios, making it an attractive option for aerospace engineers seeking to minimize weight while maintaining safety standards.

Sustainable Flight Eco Friendly Materials

As I delve into the world of eco-friendly materials, I’m excited to explore how sustainable flight is becoming a reality. The use of carbon fiber in airplanes has paved the way for a new generation of materials that are not only strong and lightweight but also environmentally conscious.

By focusing on recyclable materials, the aviation industry can significantly reduce its carbon footprint, making air travel more eco-friendly for future generations.

Taking to the Skies: 5 Key Tips for Carbon Fiber in Airplanes

- Understand the significance of fibre orientation: The direction in which carbon fibres are laid can drastically affect the material’s strength and weight, making it crucial for optimal aircraft design

- Consider the trade-offs between cost and performance: While carbon fibre offers unparalleled strength-to-weight ratio, its high cost can be a barrier; understanding where to compromise is key

- Leverage advanced materials for hybrid solutions: Combining carbon fibre with other materials can lead to innovative, high-performance components that push the boundaries of flight

- Optimize manufacturing processes for reduced waste: The production of carbon fibre components can be wasteful; implementing efficient manufacturing techniques is essential for sustainability

- Stay updated on regulatory frameworks and safety standards: As the use of carbon fibre in airplanes evolves, so do the rules and guidelines; staying informed is vital for ensuring compliance and safety

Key Takeaways: Carbon Fiber in Aviation

I’ve seen the impact of carbon fiber firsthand, and it’s clear that this advanced material is revolutionizing the aerospace industry with its unparalleled strength-to-weight ratio, enabling the creation of lighter, more fuel-efficient aircraft

The use of carbon fiber in airplanes isn’t just about reducing weight; it’s also about increasing sustainability – with eco-friendly materials and production methods becoming increasingly important in the quest for greener skies

From a design engineer’s perspective, the debate between carbon fiber and traditional aluminum is essentially over – carbon fiber’s superior properties make it the go-to choice for new aircraft designs, and its applications will only continue to expand as technology advances

Elegance in the Skies

The use of carbon fiber in airplanes isn’t just about cutting-edge materials; it’s about harnessing the perfect blend of strength, weight, and aerodynamics to redefine the future of flight.

Simon Foster

Conclusion: The Future of Flight

As I reflect on the carbon fiber revolution in airplane manufacturing, it’s clear that this material has been a game-changer. From its use in advanced composites to its role in achieving lighter skies through weight reduction, carbon fiber has proven to be a versatile and efficient solution. The debate between carbon vs aluminum has also highlighted the unique benefits of carbon fiber, including its potential for sustainable flight and eco-friendly materials. Whether it’s reducing fuel consumption or enabling the creation of more complex aircraft designs, carbon fiber has opened up new possibilities for the aerospace industry.

As we look to the future, it’s exciting to think about the potential for innovation and experimentation in aircraft design. With the continued development of advanced materials and technologies, we can expect to see even more efficient, sustainable, and high-performance aircraft taking to the skies. As someone who’s passionate about the science of flight, I believe that the use of carbon fiber in airplanes is just the beginning of a new era in aviation. By embracing this technology and pushing the boundaries of what’s possible, we can create a future where air travel is not only faster and more efficient but also more environmentally friendly and accessible to all.

Frequently Asked Questions

How does the use of carbon fiber in airplanes impact their overall maintenance and repair costs?

As an aerospace engineer, I’ve seen carbon fiber reduce maintenance costs by minimizing corrosion and fatigue issues, making repairs less frequent and less costly, a game-changer for airlines and passengers alike.

What are the primary challenges in manufacturing and working with carbon fiber for aircraft construction?

As I’ve seen in my own design work, the primary challenges with carbon fiber are ensuring consistent material properties, managing production costs, and perfecting the layup process to minimize defects and maximize strength-to-weight ratios.

Can carbon fiber be used in all parts of an airplane, or are there specific components where it is more beneficial than traditional materials?

While carbon fiber is incredibly versatile, it’s not a one-size-fits-all solution. I’ve found it’s particularly beneficial for components like wings, fuselage, and control surfaces, where its high strength-to-weight ratio shines. However, for certain parts like engine mounts or landing gear, traditional metals are still the better choice due to their unique requirements for durability and shock absorption.