I still remember the first time I saw a plane made from advances in composite materials for aircraft take to the sky. The way it soared through the air, its lightweight yet incredibly strong frame gliding effortlessly, was a true marvel. As an aerospace engineer, I’ve had the privilege of working on numerous projects that have pushed the boundaries of what’s possible with composite materials. But despite the hype surrounding these new materials, I’ve often found myself frustrated with the overly complicated explanations and expensive solutions that seem to dominate the industry.

As someone who’s passionate about demystifying the science behind flight, I want to cut through the noise and provide you with a clear, no-nonsense understanding of how advances in composite materials for aircraft are revolutionizing the way we design and build planes. In this article, I’ll share my personal experiences and insights, gained from years of working in the field, to give you a deeper appreciation for the real magic that happens when composite materials meet clever engineering. My goal is to inspire a sense of wonder and curiosity in you, and to show you that the principles of flight aren’t as mysterious as they seem. So, let’s dive in and explore the fascinating world of composite materials and their role in shaping the future of aviation.

Table of Contents

- Revolutionizing Flight Materials

- Advances in Composite Materials for Aircraft

- 5 Key Takeaways: Harnessing the Power of Advanced Composites in Aircraft Design

- Key Takeaways: Revolutionizing Aerospace with Composite Materials

- Shaping the Future of Flight

- Taking to the Skies with Innovation

- Frequently Asked Questions

Revolutionizing Flight Materials

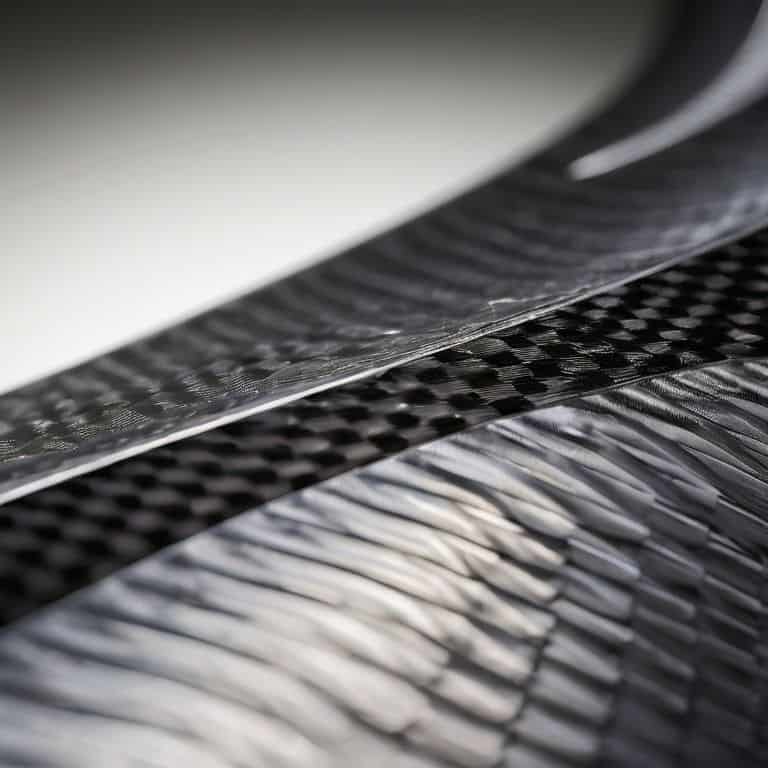

As I delve into the world of composite materials, I’m reminded of the carbon fiber reinforced polymers that have become a staple in aviation. These materials have revolutionized the way we design and build aircraft, allowing for significant reductions in weight while maintaining incredible strength. I recall working on a project where we utilized advanced materials for aircraft structures, and the results were astounding – we were able to increase fuel efficiency by a substantial margin.

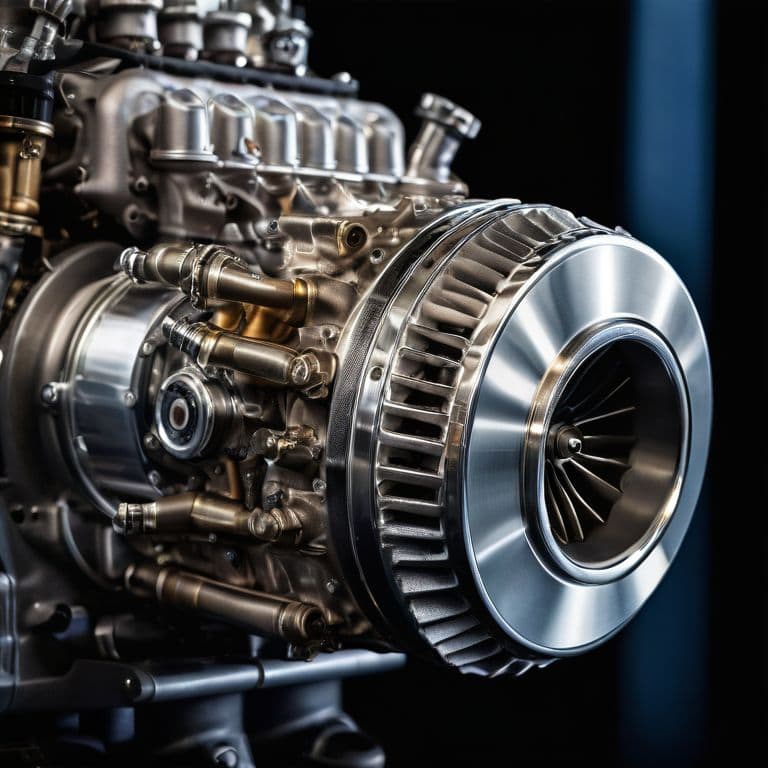

One of the most exciting developments in this field is the use of nanomaterials for aerospace applications. These tiny materials have unique properties that make them ideal for use in aircraft manufacturing. For instance, they can be used to create ultra-strong, lightweight composites that can withstand the harsh conditions of flight. I’ve seen firsthand how these materials can be used to create complex components, such as engine parts, using 3D printing in aircraft manufacturing.

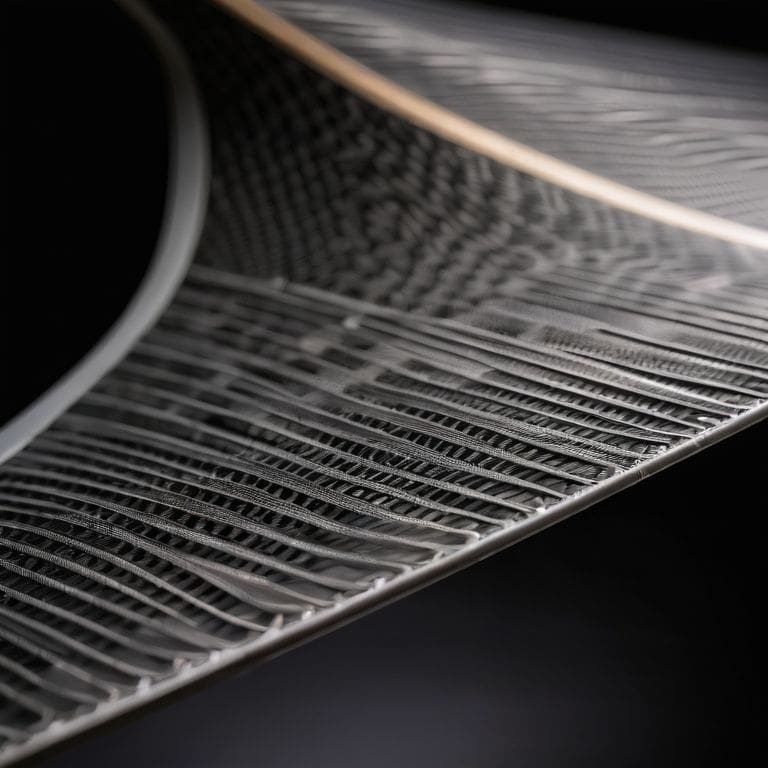

As we continue to push the boundaries of what’s possible with composite materials, we’re also exploring ways to make them more sustainable. This includes developing sustainable composite materials for flight that can be easily recycled or reused. By reducing waste and minimizing the environmental impact of aircraft production, we can create a more eco-friendly industry. Additionally, advancements in composite material fatigue analysis are helping us to better understand how these materials behave over time, allowing us to design even safer and more efficient aircraft.

Carbon Fiber Polymers Take Center Stage

As I delve into the world of composite materials, I’m excited to share with you the impact of carbon fiber polymers. These materials have become a staple in aircraft design, offering unparalleled strength-to-weight ratios.

The use of lightweight composites has been a major factor in reducing fuel consumption and increasing flight efficiency.

Nanomaterials Boost Aerospace Efficiency

As I delve into the latest advancements, I’m excited to share how nanomaterials are being leveraged to enhance aerospace efficiency. By incorporating these tiny powerhouses into aircraft design, we’re seeing significant improvements in strength-to-weight ratios, which is a critical factor in determining an aircraft’s overall performance.

The use of advanced nanocomposites is allowing us to push the boundaries of what’s possible in terms of weight reduction and durability. This, in turn, is enabling the creation of more fuel-efficient aircraft, which is a major step forward in our quest to make air travel more sustainable and environmentally friendly.

Advances in Composite Materials for Aircraft

As I delve into the world of carbon fiber reinforced polymers in aviation, I’m constantly amazed by their impact on flight efficiency. These advanced materials have become a cornerstone in modern aircraft design, enabling the creation of stronger, lighter structures that significantly reduce fuel consumption. By leveraging the unique properties of carbon fiber, engineers can craft complex components with unprecedented precision, which in turn, enhances overall aircraft performance.

The integration of nanomaterials for aerospace applications is another area that holds tremendous promise. By incorporating these tiny, high-performance materials into composite structures, researchers can fine-tune their mechanical properties to achieve optimal strength-to-weight ratios. This synergy between nanomaterials and traditional composites has the potential to revolutionize the way we design and build aircraft, making them more sustainable and environmentally friendly.

In my experience, the key to successfully implementing these advanced materials for aircraft structures lies in understanding their behavior under various stress conditions. Composite material fatigue analysis is a critical aspect of this process, as it helps engineers predict and mitigate potential failure points. By combining cutting-edge materials with rigorous testing and simulation protocols, we can unlock new levels of efficiency and safety in flight, paving the way for a more exciting and sustainable future in aviation.

3d Printing Overhauls Manufacturing Processes

As I delve into the world of aircraft manufacturing, I’m excited to share how 3D printing technology is transforming the way we build planes. This innovative method allows for the creation of complex geometries and structures that cannot be produced with traditional manufacturing techniques. By enabling the rapid production of customized parts, 3D printing is streamlining the manufacturing process and reducing production time.

The use of 3D printing in aircraft manufacturing has also led to a significant reduction in material waste. With the ability to print on demand, manufacturers can produce parts as needed, rather than having to stockpile excess materials. This not only saves resources but also reduces the environmental impact of the manufacturing process.

Sustainable Composites Reduce Fatigue Risk

As I delve into the world of sustainable composites, I’m excited to share how they’re reducing fatigue risk in aircraft. The use of recycled materials in composite manufacturing is becoming increasingly popular, and for good reason. By reusing materials, we’re not only reducing waste but also creating stronger, more durable components.

The implementation of fatigue-resistant composites is a significant breakthrough in aircraft design. This innovation enables engineers to design planes that can withstand the stresses of flight for longer periods, reducing the need for frequent repairs and maintenance.

5 Key Takeaways: Harnessing the Power of Advanced Composites in Aircraft Design

- Optimize material selection by understanding the trade-offs between weight, strength, and durability to achieve the perfect balance for your aircraft’s specific needs

- Integrate 3D printing technology into your manufacturing process to create complex geometries and reduce material waste, leading to more efficient and cost-effective production

- Explore the potential of nanomaterials to enhance the mechanical properties of composites, such as increased toughness and resistance to fatigue, which can significantly improve aircraft performance and safety

- Implement sustainable composite materials and manufacturing methods to minimize environmental impact and reduce the risk of material fatigue, ensuring a longer lifespan for your aircraft

- Leverage advanced simulation tools and testing methods to validate the performance of composite materials under various flight conditions, allowing for more accurate predictions and optimizations in aircraft design

Key Takeaways: Revolutionizing Aerospace with Composite Materials

I’ve witnessed the transformative power of advanced composite materials in aircraft design, significantly enhancing efficiency and safety by reducing weight while maintaining or even increasing strength

The integration of cutting-edge technologies like 3D printing and nanomaterials is not only streamlining manufacturing processes but also paving the way for sustainable and fatigue-resistant composites that redefine the future of flight

By embracing these innovations, the aerospace industry is poised to make significant strides in reducing environmental impact, improving passenger safety, and pushing the boundaries of what is possible in aircraft design and performance

Shaping the Future of Flight

The most thrilling aspect of advances in composite materials for aircraft isn’t just their potential to make flights more efficient and safer, but how they’re inspiring a new generation of engineers to push the boundaries of what’s possible in the skies.

Simon Foster

Taking to the Skies with Innovation

As I reflect on the revolutionary impact of advances in composite materials for aircraft, it’s clear that we’ve only scratched the surface of what’s possible. From carbon fiber polymers to nanomaterials, and from 3D printing to sustainable composites, each innovation has built upon the last, creating a synergy that’s transforming the aerospace industry. The efficiency, safety, and performance gains we’ve seen are a testament to human ingenuity and the relentless pursuit of aerodynamic perfection. As someone who’s spent their career in the trenches of aircraft design, it’s exhilarating to see these advancements taking flight.

As we look to the future, it’s essential to remember that the art of flight is, at its core, a beautiful blend of science, engineering, and imagination. The boundless potential of composite materials will continue to inspire new generations of engineers, designers, and innovators to push the envelope of what’s thought possible. And as we soar to new heights, let’s not forget the elegant simplicity of the principles that govern our journey, for it’s in the harmony of form and function that we find true aerodynamic elegance.

Frequently Asked Questions

How do advancements in composite materials impact the overall weight and fuel efficiency of commercial aircraft?

By leveraging advanced composites, we’ve significantly reduced aircraft weight while maintaining strength, which directly translates to improved fuel efficiency. I’ve seen this in my own designs – lighter planes mean less fuel burn, reducing operating costs and environmental impact. It’s a win-win for airlines and the planet.

What role do nanomaterials play in enhancing the durability and performance of composite materials in aerospace applications?

Nanomaterials are a total breakthrough for aerospace composites, allowing us to create incredibly strong, yet lightweight materials. By incorporating nanomaterials, we can significantly enhance durability and performance, reducing the risk of fatigue and improving overall efficiency. It’s a key area of research for me, and I’m excited to see where it takes us.

Can 3D printing technologies be used to create complex composite structures that cannot be produced with traditional manufacturing methods?

I’ve seen 3D printing revolutionize our workshop, allowing us to craft intricate composite structures that would be impossible with traditional methods. This technology enables the creation of complex geometries and internal structures, which can significantly enhance an aircraft’s performance and efficiency.