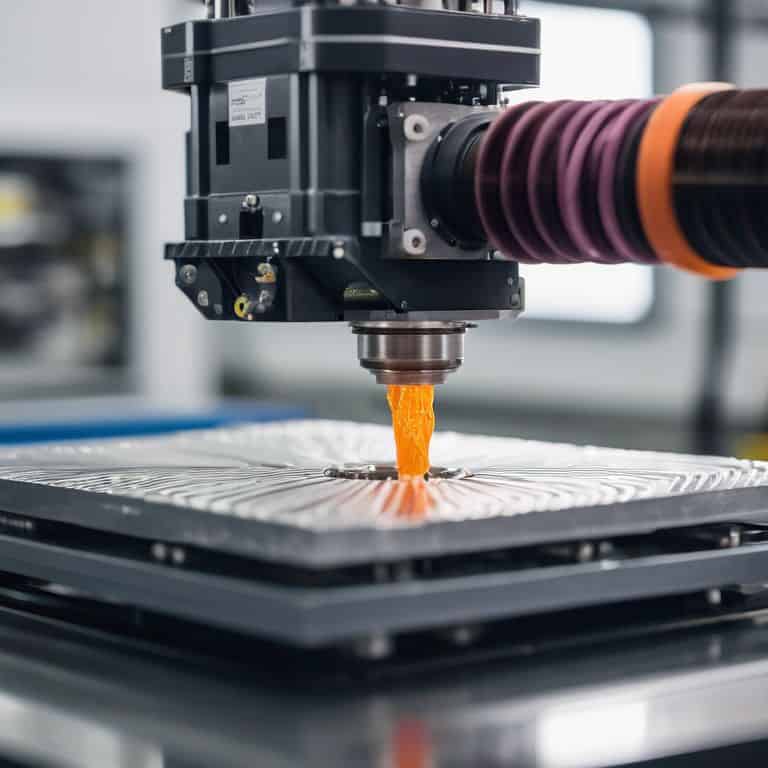

I still remember the first time I saw a 3D printed aircraft component up close – it was like witnessing a mini-revolution in the making. The way it was crafted, layer by layer, with precision and perfection, was a testament to the power of innovation in the aviation industry. As someone who’s spent years studying how 3d printing is revolutionizing aircraft parts, I’ve come to realize that it’s not just about the flashy new technologies, but about the unseen improvements that make air travel safer and more efficient. The real magic happens in the logistics and design phases, where clever engineers and manufacturers are using 3D printing to create complex parts that were previously impossible to produce.

As I delve into the world of 3D printing in aviation, I promise to cut through the hype and bring you practical insights from my own experiences as a systems consultant. I’ll share real-life examples of how 3D printing is being used to improve aircraft design, reduce production times, and increase safety. My goal is to give you a behind-the-scenes look at the incredible work being done in this field, and to show you how smarter logistics and innovative design are making modern flight possible. Whether you’re an industry insider or just curious about the future of aviation, I invite you to join me on this journey into the fascinating world of 3D printing in aircraft parts.

Table of Contents

Revolutionizing Aircraft Parts

As I delve into the world of additive manufacturing in aerospace, I’m constantly amazed by the sheer potential of 3D printing to transform the way we produce aircraft parts. One of the most significant advantages of this technology is the ability to create complex components with faster production times, reducing the need for lengthy tooling and manufacturing processes. This not only saves time but also allows for cost-effective production, making it an attractive option for airlines and manufacturers looking to reduce costs.

The impact of 3D printing on supply chain management cannot be overstated. With the ability to produce parts on demand, airlines can reduce their inventory costs and minimize the need for costly storage facilities. This, in turn, enables them to respond more quickly to changing demand patterns and reduce the risk of obsolete inventory. Companies like GE Aviation are already leveraging 3D printed aircraft engine components to improve efficiency and reduce waste.

As I explore the possibilities of 3D printing in aviation, I’m excited to see the potential for revolutionizing supply chain management and improving the overall efficiency of aircraft production. With the ability to produce complex components quickly and cost-effectively, the future of aviation is looking brighter than ever.

Additive Manufacturing in Aerospace Takes Off

As I delve into the world of additive manufacturing in aerospace, I’m struck by the precision it brings to the table. The ability to create complex components with reduced material waste is a game-changer.

The efficiency gains from additive manufacturing are being felt across the industry, from reduced production times to increased component reliability.

Faster Production With 3d Printing Technology

As I delve into the world of 3D printing in aerospace, I’m struck by the potential for faster production cycles. This technology allows for the rapid creation of complex components, significantly reducing the time it takes to get parts from design to deployment. I’ve seen it in action, and the results are astounding.

The impact of 3D printing on production timelines is further amplified by the ability to create parts on demand, reducing the need for extensive inventory storage and management. This not only saves space but also cuts down on waste, making the entire process more efficient and cost-effective.

3d Printing Innovates Supply Chains

As I delve into the world of additive manufacturing in aerospace, I’m struck by the potential of 3D printing to innovate supply chains. By producing aircraft parts on demand, airlines and manufacturers can reduce inventory costs and minimize waste. This shift towards cost-effective aircraft part production is a game-changer for the industry, enabling companies to allocate resources more efficiently.

The impact of 3D printing on supply chain management is multifaceted. For instance, faster production with 3D printing technology allows for rapid prototyping and testing, reducing the time it takes to bring new parts to market. This, in turn, enables airlines to respond more quickly to changing demand and maintenance needs. Companies like GE Aviation are already leveraging 3D printed aircraft engine components to improve performance and reduce lead times.

By embracing additive manufacturing, the aerospace industry can create more agile supply chains, better equipped to handle the complexities of modern air travel. As someone who’s passionate about the behind-the-scenes systems that make flying possible, I find it exciting to think about the potential for revolutionizing supply chain management through 3D printing. This technology has the potential to streamline logistics, reduce costs, and ultimately make air travel safer and more efficient.

Cost Effective Production With 3d Printed Components

As I’ve delved into the world of 3D printing in aviation, I’ve been impressed by the cost savings it offers. By producing components on-demand, airlines and manufacturers can reduce inventory costs and minimize waste. This approach also enables the creation of complex geometries that cannot be produced with traditional manufacturing methods, leading to lighter components that improve fuel efficiency.

The use of 3D printed components also reduces the need for costly tooling and molds, making it an attractive option for low-volume production runs. Additionally, the ability to print replacement parts as needed can significantly reduce lead times and maintenance downtime, resulting in significant operational savings for airlines and airports.

Ge Aviation 3d Printing Innovations Lead

As I delve into the world of 3D printing in aviation, I’m constantly impressed by companies like GE Aviation, which are pioneering new approaches to manufacturing. Their use of additive manufacturing is not only reducing production times but also allowing for the creation of complex components that cannot be produced through traditional methods.

The innovative spirit of GE Aviation is evident in their investment in 3D printing technology, which has led to significant advancements in the field. By leveraging this technology, they’re able to produce parts with increased efficiency and precision, ultimately contributing to the development of more reliable and sustainable aircraft.

5 Key Takeaways: Harnessing the Power of 3D Printing in Aircraft Parts

- Design for Manufacturability: Understanding how 3D printing enables the creation of complex geometries and internal structures that cannot be produced with traditional manufacturing methods

- Material Science Breakthroughs: Exploring the development of new, high-performance materials tailored for 3D printing, such as advanced alloys and composites

- Supply Chain Optimization: Leveraging 3D printing to reduce inventory, increase local production, and minimize logistical challenges in the aerospace industry

- Regulatory Frameworks and Standards: Staying ahead of the curve on evolving regulatory requirements and standards for the use of 3D printed parts in commercial and private aviation

- Workforce Training and Adoption: Fostering a culture of innovation and providing the necessary training for engineers, technicians, and operators to effectively integrate 3D printing into their workflows and daily operations

Key Takeaways for the Future of Aviation

I’ve witnessed how 3D printing is transforming the production of aircraft components, enabling faster, more cost-effective, and environmentally friendly manufacturing processes

The integration of additive manufacturing in aerospace is not only improving supply chains but also paving the way for innovative designs and materials that can significantly enhance aircraft performance and safety

By embracing these unseen innovations, the aviation industry can unlock new levels of efficiency, sustainability, and passenger experience, ultimately shaping the future of flight and making it more accessible and exciting for everyone

Revolutionizing the Skies

I firmly believe that 3D printing is not just a tool for building aircraft parts, but a catalyst for a fundamental shift in how we design, produce, and maintain the complex systems that keep our planes flying safely and efficiently.

Oliver Byrne

Taking Flight into the Future

As I reflect on the impact of 3D printing on aircraft parts, it’s clear that this technology is revolutionizing the way we design, produce, and maintain planes. From faster production and cost-effective components to innovative supply chain solutions, the benefits are numerous. Companies like GE Aviation are leading the charge, leveraging 3D printing to create complex parts and reduce waste. The results are undeniable: lighter, more efficient aircraft that are safer and more reliable.

As we look to the future of aviation, it’s exciting to think about the role 3D printing will play in shaping the industry. With its potential to transform logistics and streamline operations, this technology is poised to make a significant impact on the way we travel. As someone who’s passionate about the unseen innovations that make flying possible, I’m eager to see what’s next for 3D printing in aerospace. One thing is certain: the future of flight has never looked brighter, and the possibilities are endless.

Frequently Asked Questions

How does 3D printing affect the overall weight and fuel efficiency of aircraft?

I’ve seen how 3D printing can significantly reduce aircraft weight by creating complex, hollow structures that maintain strength while using less material, which in turn boosts fuel efficiency and lowers emissions – a game-changer for the aviation industry.

What are the current limitations and challenges of implementing 3D printing technology in aircraft part production?

While 3D printing is a game-changer, it’s not without its challenges – scalability, material certification, and regulatory frameworks are still being ironed out, slowing adoption in aircraft part production, and requiring careful consideration to ensure safety and efficiency.

Can 3D printed aircraft parts meet the same safety and regulatory standards as traditionally manufactured components?

I’ve seen 3D printed parts undergo rigorous testing and certification, meeting or exceeding traditional standards. Regulatory bodies like the FAA are working closely with manufacturers to establish clear guidelines, ensuring these innovative components are just as safe and reliable as their traditionally made counterparts.