I still remember the first time I saw a plane made with advances in lightweight composite materials. I was at an airshow, and the presenter was going on about how these new materials were going to revolutionize the aviation industry. But as I looked at the plane, I couldn’t help but think about all the hype surrounding it. Everyone was talking about how lightweight composite materials were the future of flight, but few people were discussing the actual challenges and benefits of implementing them. As someone who’s spent years working in aviation, I’ve seen my fair share of overhyped innovations that never quite lived up to the promise.

In this article, I want to cut through the noise and give you a no-nonsense look at the reality of advances in lightweight composite materials. I’ll share my personal experiences and insights from working with airlines and airports to implement these materials, and I’ll provide you with a clear understanding of what they can and can’t do. My goal is to give you a practical understanding of how these materials are changing the aviation industry, and what that means for the future of flight. I’ll focus on the real benefits and challenges of using lightweight composite materials, and I’ll explain how they’re being used to improve efficiency, safety, and sustainability in aviation.

Table of Contents

- Advances in Lightweight Composite Materials

- Sustainable Future of Aviation Materials

- Lightweight Composite Manufacturing Techniques Evolve

- Sustainable Composite Materials for Future Applications

- 5 Key Takeaways: Harnessing the Power of Lightweight Composite Materials

- Key Takeaways: Revolutionizing Aviation with Lightweight Composites

- Shaping the Future of Flight

- Revolutionizing Flight: The Future of Lightweight Composites

- Frequently Asked Questions

Advances in Lightweight Composite Materials

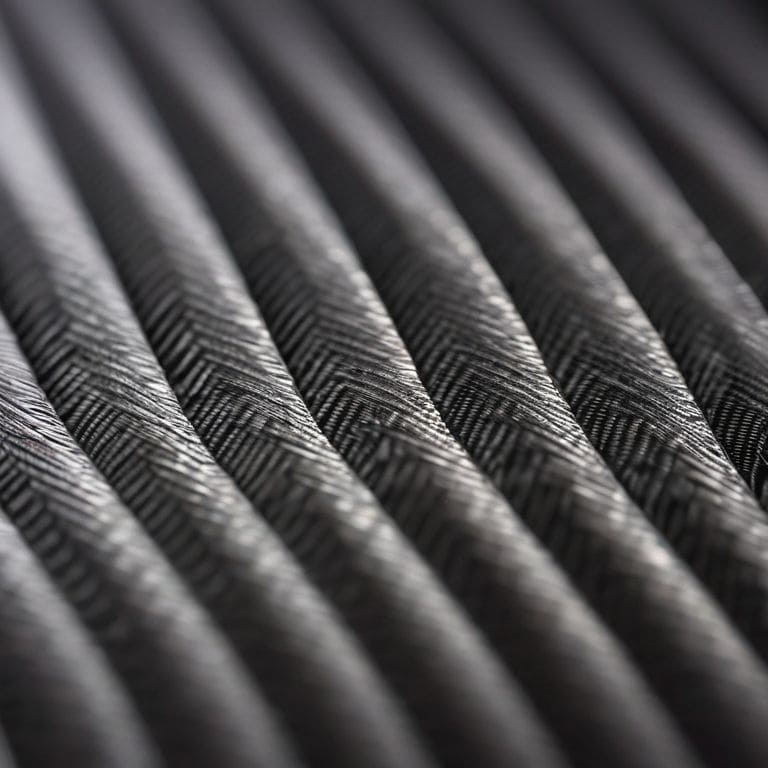

As I delve into the world of carbon fiber reinforced polymers, I’m struck by the sheer potential of these advanced materials in aerospace. The ability to craft stronger, lighter components is revolutionizing the way we build planes. I’ve had the chance to explore various lightweight composite manufacturing techniques, and it’s astounding to see how they’re being used to create more efficient aircraft.

One of the most significant benefits of these new materials is their improved durability. By incorporating nanostructured composites, manufacturers can create parts that are not only lighter but also more resistant to wear and tear. This means less maintenance, reduced fuel consumption, and a lower overall environmental impact. It’s exciting to think about the potential applications of sustainable composite materials in future aircraft designs.

The use of composite materials is not limited to the aerospace industry, of course. I’ve also been following developments in the composite materials in automotive industry, where similar techniques are being used to create lighter, more fuel-efficient vehicles. As someone who’s passionate about urban planning and photography, I’m fascinated by the potential for these advancements to shape the future of transportation as a whole. By embracing innovative materials and manufacturing techniques, we can create a more efficient, sustainable, and connected world.

Carbon Fiber Reinforced Polymers Take Flight

As I delve into the specifics of lightweight composite materials, I’m excited to explore how carbon fiber reinforced polymers are transforming aircraft design. These advanced materials are being used to build stronger, lighter planes that can fly farther and more efficiently.

The use of carbon fiber reinforced polymers in aircraft construction is a game-changer, enabling the creation of complex shapes and structures that would be impossible with traditional materials.

Nanostructured Composites for Improved Durability

As I delve into the world of nanostructured composites, I’m excited to see how they’re enhancing aircraft durability. The use of nano-scale materials is allowing for the creation of stronger, more resistant components. This, in turn, is leading to reduced maintenance costs and increased safety for passengers.

The integration of advanced nanomaterials into composite structures is a game-changer for the aviation industry. By improving the mechanical properties of these materials, manufacturers can build more efficient and reliable aircraft. I’ve seen this technology being tested in various applications, from engine components to fuselage design, and the results are promising.

Sustainable Future of Aviation Materials

As I delve into the sustainable future of aviation materials, I’m excited to explore the potential of carbon fiber reinforced polymers in reducing the environmental footprint of air travel. These advanced materials have already shown promise in reducing fuel consumption and emissions, and I believe they will play a crucial role in shaping the future of aviation.

The use of nanostructured composites is another area that holds great potential for sustainable aviation materials. By improving durability and reducing maintenance needs, these materials can help minimize waste and reduce the demand for new raw materials. I’ve seen firsthand how lightweight composite manufacturing techniques can be applied to create stronger, more efficient aircraft components, and I’m eager to see how these techniques will evolve in the coming years.

As the aviation industry continues to push towards a more sustainable future, I expect to see a growing overlap between advanced materials in aerospace and the composite materials in automotive industry. By sharing knowledge and best practices, these industries can drive innovation and accelerate the development of sustainable materials that benefit both sectors.

Lightweight Composite Manufacturing Techniques Evolve

As I’ve delved into the world of lightweight composite materials, I’ve noticed a significant shift in manufacturing techniques. The way we produce these materials is becoming increasingly sophisticated, allowing for greater precision and efficiency. This, in turn, enables the creation of stronger, lighter components that can be used in a variety of aircraft applications.

The evolution of manufacturing techniques has also led to the development of more complex composite structures, which can be tailored to specific performance requirements. For instance, advanced 3D printing methods are being used to create intricate geometries that cannot be produced using traditional manufacturing methods, further expanding the possibilities for lightweight composite design.

Sustainable Composite Materials for Future Applications

As I delve into the world of sustainable composite materials, I’m excited to explore how biodegradable composites are being developed for future applications. These innovative materials have the potential to significantly reduce the environmental impact of aviation, making it a more eco-friendly industry.

The use of renewable resources in composite materials is a game-changer, allowing for the creation of stronger, lighter, and more sustainable aircraft components. This shift towards eco-friendly materials is not only beneficial for the environment, but also opens up new possibilities for aircraft design and functionality.

5 Key Takeaways: Harnessing the Power of Lightweight Composite Materials

- Adopt a holistic approach to aircraft design, considering the entire lifecycle of the plane to maximize the benefits of lightweight composite materials

- Invest in research and development to stay ahead of the curve in nanostructured composites and other emerging technologies

- Implement sustainable manufacturing techniques to reduce waste and minimize environmental impact

- Collaborate with industry partners to standardize the use of lightweight composite materials and drive down costs

- Consider the potential for lightweight composite materials to enable new aircraft designs and operational efficiencies, rather than just focusing on incremental improvements to existing models

Key Takeaways: Revolutionizing Aviation with Lightweight Composites

I’ve witnessed how advancements in carbon fiber reinforced polymers and nanostructured composites are significantly enhancing aircraft durability and fuel efficiency, making them a cornerstone of modern aviation innovation

The evolution of lightweight composite manufacturing techniques is not only reducing production costs but also paving the way for more sustainable materials to be integrated into aircraft design, promising a greener future for flight

By adopting sustainable composite materials and leveraging innovative manufacturing methods, the aviation industry is poised to achieve unprecedented levels of efficiency, safety, and environmental sustainability, redefining the future of air travel

Shaping the Future of Flight

As I see it, the true magic of advances in lightweight composite materials isn’t just about making planes lighter, it’s about revolutionizing the entire aviation ecosystem – from design and manufacturing to operational efficiency and sustainability.

Oliver Byrne

Revolutionizing Flight: The Future of Lightweight Composites

As I reflect on the advances in lightweight composite materials, it’s clear that these innovations are not just about making planes lighter and stronger, but about transforming the entire aviation industry. From carbon fiber reinforced polymers to nanostructured composites, we’ve seen significant improvements in durability and efficiency. The evolution of manufacturing techniques and the development of sustainable composite materials are also crucial steps towards a more environmentally friendly future for air travel. By embracing these changes, we can create a safer, more efficient, and more sustainable aviation system.

As we look to the future, it’s exciting to think about the potential of lightweight composites to revolutionize flight and make air travel more accessible to everyone. By continuing to push the boundaries of what’s possible with these materials, we can unlock new opportunities for innovation and growth, and create a brighter, more sustainable future for generations to come. The invisible revolution of lightweight composites may not always grab the headlines, but its impact on the aviation industry will be felt for years to come.

Frequently Asked Questions

How will the increased use of lightweight composite materials impact the overall cost of aircraft production?

As I’ve seen in my consulting work, the increased use of lightweight composites will likely lead to higher upfront production costs, but these will be offset by long-term savings on fuel and maintenance, making aircraft more economical over their lifespan.

What are the potential challenges and limitations of implementing nanostructured composites in commercial aircraft?

As I’ve seen in my consulting work, implementing nanostructured composites in commercial aircraft poses challenges like scalability, cost, and standardization. Ensuring consistent quality and meeting stringent regulatory requirements are also key hurdles to overcome, but the potential payoff in improved durability and efficiency makes it an exciting area of research.

Can sustainable composite materials be used in existing aircraft designs, or will they require significant redesigns and retrofits?

While some sustainable composite materials can be integrated into existing aircraft designs, others may require significant redesigns or retrofits. I’ve seen cases where novel materials have been used to upgrade legacy planes, but a full overhaul of the design is often needed to maximize their benefits, especially when it comes to structural components.